site map

Jowett Jupiter Specifications, Performance and Statistics

Jowett Jupiter first appeared in the London Motor Show, October, 1949 as a rolling chassis, having been

designed in four months by the famous (of Auto Union pre-war, and Cisitalia immediately

postwar) Austrian engineer Dr Robert Eberan-Eberhorst.

The tubular chassis was made from a relatively light-weight but equally-strong steel, high

in chromium and molybdenum; it had been developed for fighter aeroplanes like the Spitfire. Nice for us is that it does not

rust!. Bodywork was designed (also,

astonishingly in view of its complexity and beauty, also in four

months) in-house by

Jowett's body stylist Reg Korner, made form aluminium alloy. The first two

complete Jupiters were on the road by March 1950. The

third Jupiter raced at Le Mans in June 1950 and won its class.

Initially it was named the Javelin-Jupiter but after a while it was re-named the Jowett Jupiter.

First

production batch of Jupiters (five) were completed at the Works

September to December 1950. One was shipped to the French agent, the

other four were road-test, demonstrator and show cars.

The very

last Jupiter left the Jowett factory in November 1954. The Jowett

factory built 827 standard-bodied Jupiters during those years, of which

733 were the Mk1 and 94 were the Mk1a.

But also a further 74 Jupiters went out as fully equipped rolling chassis

normally to coachbuolder to build special bodies on them, however

three of these rolling chassis later received standard bodywork making

830 the total number of standard Jupiters that once existed. It has

been established that 64 of the rolling chassis are known to have

received coachbuilt bodies, the fate is unknown of the others.

See below for the

Jupiter's standard tool list and images showing what some of the items look like. Also below, a cmparison of how the Mk1a differed from the Mk1.

Engine.

The Jowett Jupiter engine is a good example

of British engineering eccentricity. It was designed by Gerry Palmer

(he also designed the Jowett Javelin, and later the MG Magnette,

Wolseley 4/44 and variants)

This engine was his first and last engine design, initially for the

Jowett Javelin. It is a horizontally opposed four cylinder unit

(Flat-Four) of bore

72.5mm x stroke 90mm swept volume 1486cc. (90.6cu-in). Compression

ration 7.6:1 or 8:1

dependent upon destination country's petrol. the version for the

Jupiter was developed to produce some more power than that needed for

the Javelin.

The

Javelin version of te enginme developed 52.5 BHP wheras the Jupiter

version - same swept volume (1486cc) but higher compression and different carburettors, developed 62.5 BHP with even more

deveoped for the Mans Jupiters

|

Left: rear view of a Jowett Jupiter engine but without the

two carburettors. At the top is the housing of the updated (throwaway) oil filter. Below one of the heads

the left side exhaust manifold can be seen. The clutch housing is detachable; gearbox and

starter motor attach to the clutch housing. Beneath the black cover-plates on the top of

the engine the pushrods can be accessed. Aluminium covers (extreme right and left) hide

the rocker gear. The whole engine is sealed and runs under a slight vacuum -

positive crankcase ventilation - universal today but a novelty when the engine was

designed in 1946. |

| Right: view of the engine installed in a

Jupiter. The water pump pulley can be seen at the top, with oil filler pipe and dipstick

below. One of the carburettors and the Lucas distributor can be made out on the left, as

can the aluminium water transfer pipe which connects the head coolant to the crankcase

front water channel - the water then flows round the front timing cover to the water pump

at the top. The strange white object top left is part of the Jupiter bodywork, since the

whole of the bonnet is hinged up for the photograph. Red stripe is wing piping |

|

Overhead valves are operated by rather long pushrods from a central camshaft mounted

directly in the crankcase above the crank. Camshaft end-float adjuster can be made out in

the above engine-installed photograph, just below the filler pipe.

|

Another view of an engine installed in a Jupiter.

This is in the last Jupiter built, the Mk1a owned by Pat Lockyer. He

rebuilt the engine himself after welding up a crack in the aluminium crankcase that was letting water

into the sump.

As with everything Pat Lockyer did, this engine runs silently, superbly, and

the car travels swiftly. |

For the standard engine, maximum power occurs at 4,500rpm (Standard

Jupiter Mk1, Mk1a) and 5100rpm (Jupiter type R4 which had a

slightly raised 8.5:1

compression ratio). Crank is 3-bearing hardened type. The crankcase

block is of aluminium alloy split into two halves vertically down

the centre-line so that the main bearing housings (and the camshaft

bearing housings) are

half in one side, half in the other, with some big big

bolts clamping both halves of the crakcase together.

The cylinder heads are cast iron - fortunately for us 70 or more years on as this makes them

relatively easy to repair and convert to lead-free petrol. Oil filter housing is a separate

casting bolted to top of engine block via an obtuse-angled vee - always a conversation

piece as it is such fun to keep oil tight. The water pump is perched above the engine as a

separate unit that also carries the fan spindle, thus the water pump has to suck hot water

from the engine, or more correctly, cylinder heads. Since the pump is joined to the top of the

engine via a small piece of hose, and since the pump is triangulated to the dynamo and

engine for fan-belt tensioning, you have to ensure that the pump does not get too close to

the distributor. Radiator is mounted above and behind the engine in a compact but unusual

layout.

Nevertheless the Jupiter's power of over 60 genuine BHP was quite good for the

period from only 1486cc. Good enough for 10 major victories in three in-era seasons.

Transmission

Compact transmission (gearbox), as designed

for the Javelin, is a separate unit from the clutch housing. It

offers 4 forward ratios

(synchromesh on 2nd, 3rd and top) plus reverse. Gear lever is

steering-column-mounted. the gearbox ewas initally made by an outside

contractor, meadows, but later Jupiters had Jowett-built interiors.

Steering

Steering is by a solidly mounted rack-and-pinion unit, rare for it's time. As a result

the steering is light and positive.

Brakes

Apart from the very early Mk1 Jupiters, the Girling brakes are all-round hydraulic with

twin leading shoes at the front. Very early Jupiters were hydraulic leading/trailing at

the front, mechanical rear, which meant that should the hydraulics fail you still had some

braking! Brake shoe area is very adequate except for fast mountain descents with heavy braking, when fade can

be experienced.

Suspension

Front suspension is independent, unequal length wishbones, with torsion rod

springs and telescopic shock absorbers.

Rear suspension (Mk1, Mk1a) is live axle, well-located by Panhard Rod (so - no axle

tramp!), with transverse torsion rod springs and telescopic shock absorbers.

Jupiter R4 is the same

except semi-elliptical leaf springs instead of torsion rods.

Interior and hood (ragtop)

The single bench seat accommodates two, but can accomodate three. It is upholstered

in leather (colour either a mid-tan or Bordeaux) while the rest of the interior is covered in a

matching ambla (rexine). Winding windows are provided. The hood folds out of sight behind the seat,

and can be raised rapidly in the event of a sudden downpour. Hoods are either beige (all

body colours except white) or black (white bodies only). White cars had Bordeaux interiors only.

Red cars had mid-tan interiors only. Other body colours could have either of these two interior colours.

Production Totals

It is confirmed that 897 cars

(all bodies) were built on the Eberhorst Jupiter frame. But another

five MAY have been built, making the maximum possible the total of 902

cars on the Eberhorst Jupiter frame. A good few had coachbuilt bodies,

as during 1950-1951 production of standard Jupiters was slow.

Also for 1952-1954 the Monte Carlo Rally no longer allowed open cars,

but for those years it did allow coachbuilders saloon-bodied cars on the chassis of

standard open cars, so some FHC Jupiters were built with the Monte Carlo Rally in mind.

The three Jupiters type R1 were on

the Eberhorst-designed chassis-frame but the Jupiter type R4 was not on

the Eberhorst-designed chassis-frame.

It is known that 829

standard-bodied Jupiters once existed, of which a good 50% still exist

in some form. many well-restored and running.

| |

Mk1 |

Mk1a |

R1 |

R4 |

| Right Hand drive |

498 |

57 |

3 |

3 |

| Left hand Drive |

233 |

37 |

0 |

0 |

| Special bodied Jupiters |

at least 64 |

1? |

|

|

These diagrams are of the Jupiter Mk1a version,

taken from a 1953 AUTOCAR magazine.

The dimensions in the above diagrams are in inches, with the seat in its central

position. Jupiter Mk1 boot locker is 25 inches x 10 inches x 31 inches

The main differences between the Mk1 and the Mk1 are:

Boot: Mk1 - internally accessible by tilting the seat back. Mk1a - externally

accessible, slightly greater capacity.

Spare wheel storage - For the Mk1 is reached through a special small door at the rear, but in

the Mk1a you have to unload the boot as it is under the boot floor..

Tankage: Mk1 - 11 Imperial gallons, Mk1a - 8 Imperial gallons.

Hood (soft top): Mk1a hood was raked further back than that of the Mk1.

Instrument Panel:

Mk1 - walnut veneer panel with recessed instruments in direct view of

the driver. Mk1a - metal panel painted body colour with chrome bezel

instruments placed

central to the car's axis. This panelwork made it much easier for RHD

and LHD Jupiters - just swap the rev counter and the speedometer - so

photo below

Leg room: Mk1 - Plenty OK for a six-footer. Mk1a - slightly less.

In sum, the Jupiter Mka has the externally accessible larger boot, and is even rarer

than the Mk1 and of

course had all the latest mechanical updates. The Jupiter Mk1 has a nicer instrument panel,

instruments, and instrument layout, and greater legroom and tankage - and is still pretty rare!

Statistics

| |

Mk1 |

Mk1 |

R4 |

R4 |

| Length |

168in |

427cm |

159in |

404cm |

| Kerb weight |

1895lb |

860kg |

1658lb |

711kg |

| Height |

56in |

142cm |

54in |

137cm |

| Width |

62in |

157cm |

62.5in |

159cm |

| Wheelbase |

93in |

236cm |

84in |

213cm |

| Track Front x rear |

52 x 50.5 |

132 x 128 |

52 x 49 |

132 x 124 |

| Power |

62.5bhp |

46.6kw |

64bhp |

47.7kw |

| Performance |

|

|

|

|

| 0 to 60mph |

14.2sec |

|

|

|

| standing quarter-mile |

21.0sec |

|

|

|

| max speed |

88mph |

142km/hr |

100mph |

161km/hr |

| Fuel consumption |

30mpg |

9.4l/100km |

|

|

The Jupiter R4 was speed-tested at MIRA (Motor Industry Research Association) test ground at

Nuneaton. It just exceeded 100mph with overdrive top engaged and the hood removed. It was

the cheapest 100mph car at the 1953 London Motor Show.

Here is the

list of tools, issued by Jowett Cars Ltd with every new Jupiter - this

actual list went out with Jupiter E1 SA 563R on 23 January 1952

Starting handle

Spare wheel,

tyre pump with connection, tyre valve key, wheel brace, jack, tommy bar

Grease gun, oil

can, axle drain plug key, sump drain plug key

Cylinder head

spanner. open-ended spanners - sizes quoted in inches:- 3/16 x 1/4", 5/15" 3/8", 7/16" x 1/2", box

spanner 5/16" x 3/8", spark plug spanner

Screwdriver,

pliers, ignition screwdriver, tube for brake bleeder valve, budget lock key

Tool roll

|

|

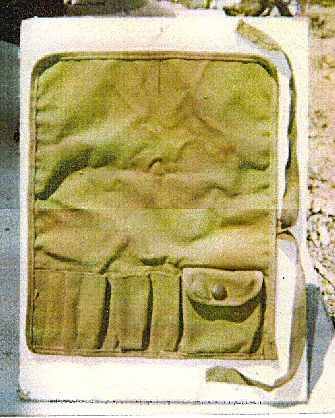

| Some of the Jupiter's tools - these are to the

correct pattern |

Close-up of the correct Jack supplied with the

Jupiter |

Here is a rear view of the Mk1a showing opening boot and symmetrical metal

instrument panel

The radio was an optional extra of course - a radio could be fitted to the Mk1 as well as the Mk1a

||Jupiter (cars!) photos||Buy the

Jupiter

Book||Buy Crowood's Javelin/Jupiter

Book||

||Magazine

Page||Magazine page start to 2003||Magazine page 2003 to 2005||Magazine page 2005 to 2008||Main

Index

Page||Famous

Jupiter Owners||

||Book

List||Competition

History||Production

History||Jowett

Genealogy||The Farina

Jupiters||

|A handbuilt car||Jowett

Clubs||Le Mans Jupitour 2000||Blois

Jupitour 2003||Jupitour

2006||Jupitour

2007||

||Quirky

Jupiter photos||A

Jupiter travels to Hyeres||